Almacenamiento: Application of Peracetic Acid (PAA) in potato storage disease management: Insights from Dr. Vijay Choppakatla

On November 4, 2024, during the “Potato Storage: The First 45 Days” webinar hosted by the North American Potato Storage Organization (NAPSO), Dr. Vijay K. Choppakatla, Director of Research and Development at BioSafe Systems, delivered a detailed

This article provides a comprehensive summary of the key points Dr. Choppakatla shared regarding PAA’s effectiveness in preventing and controlling storage diseases.

Storage Diseases and the Challenge of Prevention

Dr. Choppakatla began by highlighting the significant annual losses in the U.S. potato industry due to storage diseases. The primary storage diseases impacting potatoes include:

Late Blight

Pink Rot

Pythium Leak

Fusarium Dry Rot

Silver Scurf

Soft Rot

These diseases are caused by a variety of pathogens, such as bacteria, fungi, and oomycetes, each requiring distinct control measures. Many of these pathogens can also be carried over from the field, complicating disease management once the potatoes are stored.

The best strategy for managing these diseases is prevention, which starts in the field and continues with proper handling before potatoes are placed in storage. Dr. Choppakatla emphasized the importance of cultural, biological, and chemical control practices in reducing pathogen pressure before harvest. Additionally, surface disinfection of storage facilities and equipment, as well as treatment of tubers with chemical and biological agents prior to storage, are crucial steps.

Peracetic Acid: A Powerful Tool for Disease Control

Dr. Choppakatla introduced Peracetic Acid (PAA), a powerful disinfectant and disease management tool. PAA is formed by the reaction of hydrogen peroxide (H₂O₂) with acetic acid, creating an equilibrium compound with oxidizing properties. These properties make PAA highly effective in killing bacterial and fungal pathogens, as it disrupts their cellular structures, including lipids, proteins, and nucleic acids.

PAA is available in various compositions, with common products like StorOx 2.0 (2.0% PAA) and SaniDate 5.0 (5.3% PAA), both of which are effective in managing potato storage diseases. PAA-based solutions are clear, colorless liquids with a vinegar-like odor and are stable at ambient storage temperatures for up to two years, depending on the composition and storage conditions. Importantly, PAA products are approved for use in organic production when concentrations are below 6.0%. All PAA formulations also contain Hydrogen Peroxide as a secondary active ingredient.

PAA’s Role in Potato Storage

PAA can be used in several ways to mitigate storage diseases in potatoes:

Facility and Equipment Disinfection

Dr. Choppakatla outlined guidelines for disinfecting storage structures, equipment, and conveyors with PAA. This involves cleaning surfaces to remove organic material, followed by the application of PAA solutions (ranging from 230 PPM to 1000 PPM) with a minimum contact time of 10 minutes. A potable water rinse is required before resuming operations.

Bin Piler Spray Application

One of the most effective applications of PAA in potato storage is as a pre-storage treatment for the potatoes. A low-volume spray of PAA solution is applied to the tubers via a spray bar positioned at the top of the conveyor belt. This treatment helps reduce the likelihood of spoilage and decay from storage pathogens, such as Fusarium Dry Rot, Silver Scurf, Pink Rot, and Pythium Leak. Dr. Choppakatla advised that no rinsing should occur after the PAA application to maintain effectiveness.

Fogging in Storage

Another method for managing disease during storage is fogging. Dr. Choppakatla explained that PAA fogging, either thermal or cold, can be used within storage facilities to reduce spoilage. Fogging should occur immediately after potatoes enter storage and be repeated once a month. It is important to cover sensitive equipment, such as control panels and fan motors, to prevent corrosion during the fogging process. The recommended application rate ranges from 0.0009 to 0.0036 lbs of PAA per ton of potatoes.

For thermal fogging, Dr. Choppakatla recommended using an electric thermal fogger at temperatures ranging between 250-450°F, avoiding higher temperatures to prevent excessive CO2 buildup. Cold fogging is also effective in maintaining long-term preventative treatment by ensuring proper humidity levels in the storage environment.

Effectiveness of PAA Against Pathogens

Several studies were referenced by Dr. Choppakatla, demonstrating the effectiveness of PAA in reducing the incidence of various potato tuber diseases. For example, in a study on Fusarium Dry Rot (UWI, 2021), tubers treated with PAA exhibited significantly lower disease severity and incidence compared to untreated tubers. Similar results were observed with Soft Rot (MSU, 2014) and Pink Rot (MSU, 2011), Silver Scurf (Potato Development Centre, NB Dept. Ag, 2010; E.S. Cropconsult Ltd. 2013) where PAA treatments dramatically reduced the occurrence of these diseases.

Chemical Compatibility and Best Practices

Dr. Choppakatla also addressed the compatibility of PAA with other chemicals and products used in potato storage management. He cautioned against mixing PAA with certain pesticides and biopesticides, particularly those containing metal ions, as these can react with PAA. It is advisable to consult the manufacturer’s compatibility charts before tank mixing PAA with other products.

Furthermore, Dr. Choppakatla emphasized the importance of ensuring that surfaces and materials used in storage facilities are compatible with PAA. While PAA is generally safe for use on stainless steel, aluminum, plastic, wood, and concrete, it may cause corrosion when used on metals like copper, brass, or galvanized steel.

Conclusion: The Versatility of PAA

In closing, Dr. Choppakatla reinforced that preventative control measures are vital for successful potato storage disease management. He summarized that PAA is a versatile microbicide with broad-spectrum applications in disinfection and disease management, capable of being integrated safely with other chemical and biological control measures. However, he stressed the importance of adhering to best practices, including proper application techniques and ensuring material compatibility, to optimize PAA’s effectiveness in potato storage management.

Dr. Choppakatla’s presentation highlighted the crucial role that PAA can play in enhancing potato storage practices and reducing disease-related losses, providing potato producers with a valuable tool for maintaining crop quality throughout the storage period.

For more detailed information or inquiries, Dr. Choppakatla can be contacted at vijayc@BioSafeSystems.com.

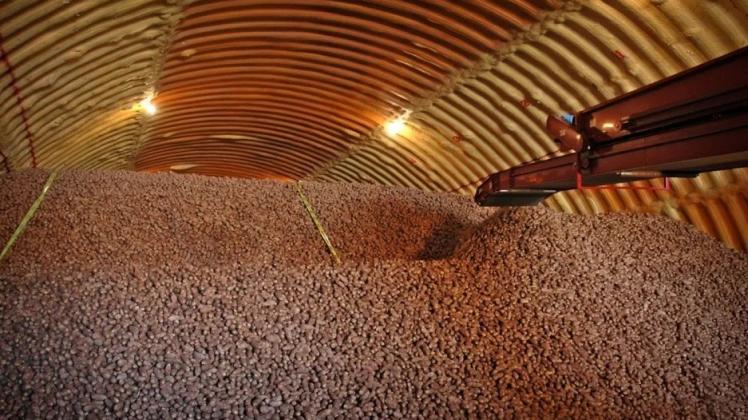

Image: Credit NAPSO

Fuente: https://www.potatonewstoday.com/2024/11/22/application-of-peracetic-acid-paa-in-potato-storage-disease-management-insights-from-dr-vijay-choppakatla/